Sublimation Printers in Vietnam Must Manage Color

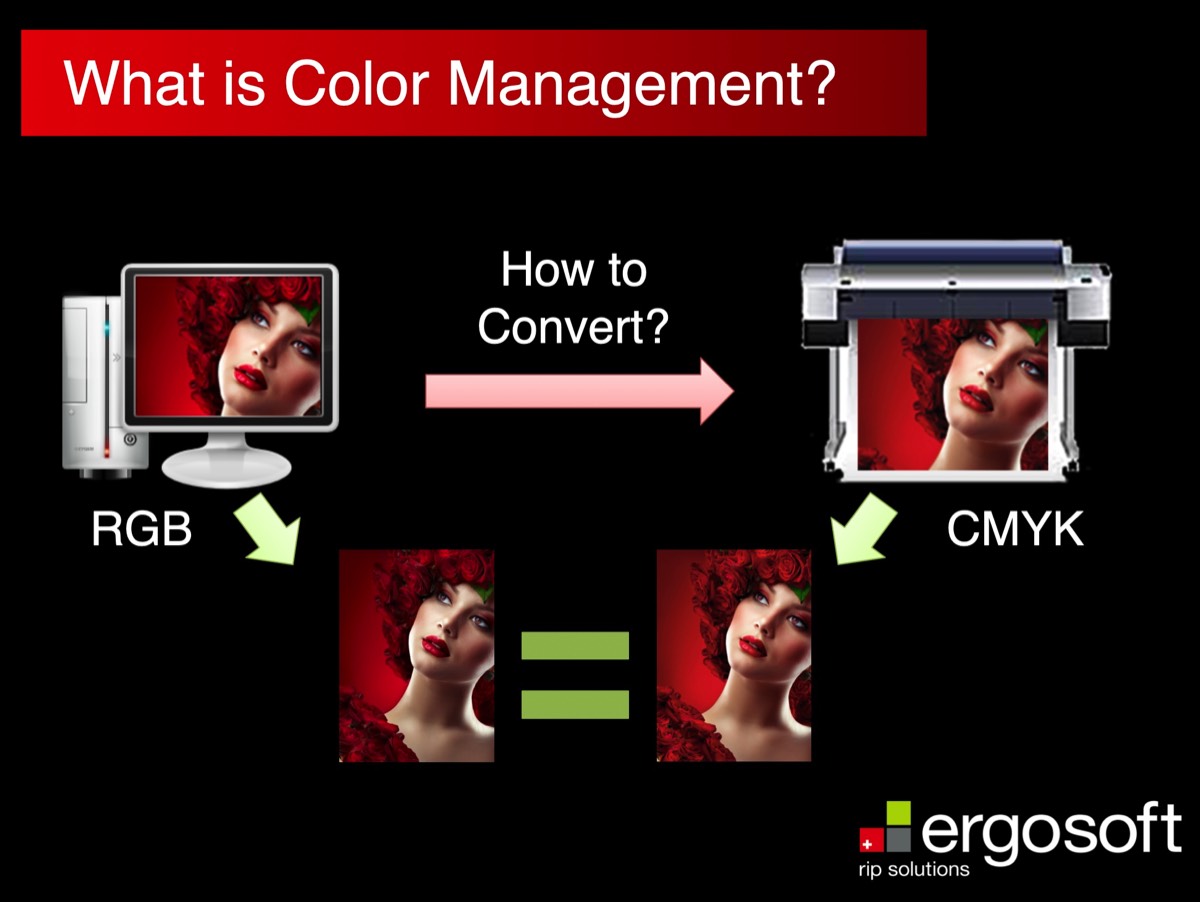

Hi, my name is Chris. I have been working with sublimation printers in Vietnam since 2008. Color management is the process of converting an RGB image on your computer screen to the print out on your CMYK digital printer. It is important and must be done well. If you do it well then the final image on the fabric will match the original artwork.

If you don't manage color well the final image will not meet the customers requirements. Sublimation printers in Vietnam will be using a color management system that converts RGB images to CMYK images.

If you don't manage color well the final image will not meet the customers requirements. Sublimation printers in Vietnam will be using a color management system that converts RGB images to CMYK images.

Produce sublimated garments in Vietnam?

Imagine that you have an idea to produce sublimated surf shorts, sports jerseys or mouse pads. Would it be great to get inside a sublimation apparel factory to see how they print and sew? Would you like to check the quality yourself? I can get you inside Vietnamese sublimation factories for a tour. Watch my video for more details.

Add your own artwork and player numbers

How can you know if the sublimation printer is good at color management?

First ask what RIP software they are using and ask why they chose it. If they go into detail why they chose it then that is a good sign that they are good at color management.

Wasatch and Ergosoft are two high end RIP softwares. If the factory is using these then that is a good sign.

Another clue as to weather they are good at color management is if they don't use a unique ICC profile for different fabrics. The fibers in a fabric and the weight of a fabric need to be adjusted for in the RIP software. If the printer is using the same ICC profile for printing on polyester fabric as cotton fabric then this is a sign that they don't manage color well.

Finally, do they have a spectrophotometer? A spectrophotometer is an instrument that measures the amount of photons (the intensity of light) absorbed after it passes through sample solution. With the spectrophotometer, the amount of a known chemical substance (concentrations) can also be determined by measuring the intensity of light detected.

May I introduce you to sublimation printers in Vietnam?

Wasatch and Ergosoft are two high end RIP softwares. If the factory is using these then that is a good sign.

Another clue as to weather they are good at color management is if they don't use a unique ICC profile for different fabrics. The fibers in a fabric and the weight of a fabric need to be adjusted for in the RIP software. If the printer is using the same ICC profile for printing on polyester fabric as cotton fabric then this is a sign that they don't manage color well.

Finally, do they have a spectrophotometer? A spectrophotometer is an instrument that measures the amount of photons (the intensity of light) absorbed after it passes through sample solution. With the spectrophotometer, the amount of a known chemical substance (concentrations) can also be determined by measuring the intensity of light detected.

May I introduce you to sublimation printers in Vietnam?

What is RIP software and why do we need it?

A raster image processor (RIP) is a software that translates (rasterizes) computer vector files (InDesign, Illustrator, Photoshop, PDF, JPG, etc.) to a raster image also known as bitmap that is composed out of a matrix of dots that the printer can understand and print. The raster image is similar to the pixels on the computer screen. The RIP software processes multiple content types for a specific print environment and communicates that processed data to the printer for final output.

RIP software enables handling many file types and file sizes. In addition, most RIP software come with ICC (International Color Consortium) color profilers and allow color management. A powerful ICC color profile management maximizes the color gamut of the inks. The RIP can also be used to enlarge images for printing without loss of detail since it increases the file resolution.

May I connect you with sublimation printers in Vietnam?

RIP software enables handling many file types and file sizes. In addition, most RIP software come with ICC (International Color Consortium) color profilers and allow color management. A powerful ICC color profile management maximizes the color gamut of the inks. The RIP can also be used to enlarge images for printing without loss of detail since it increases the file resolution.

May I connect you with sublimation printers in Vietnam?

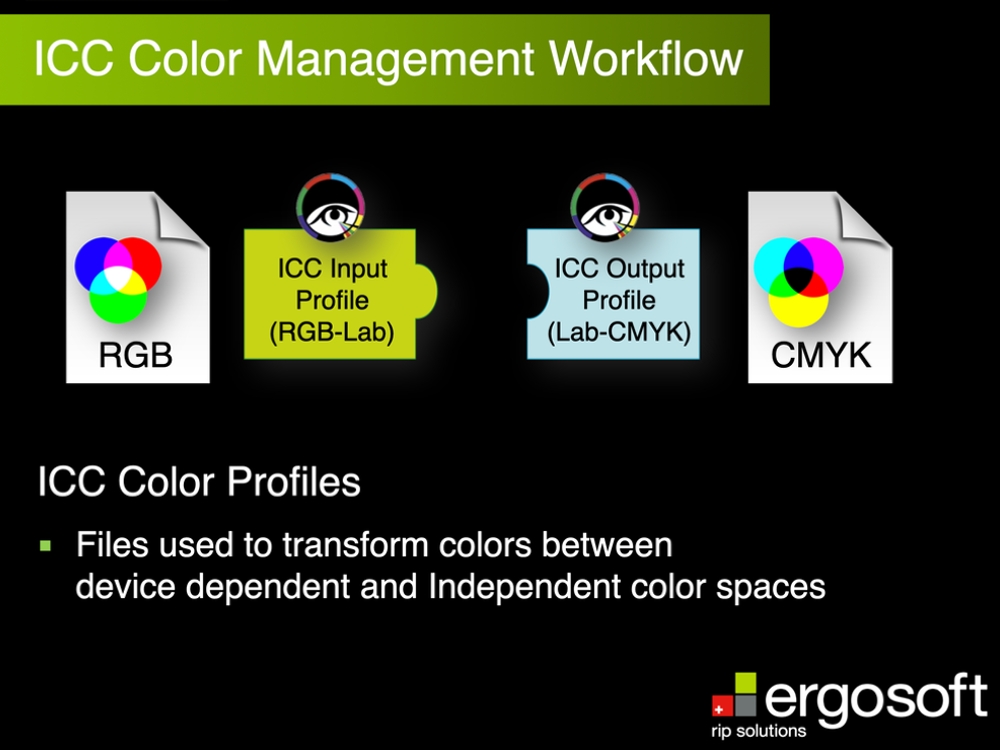

What is an ICC profile?

An ICC profile is a set of data (a file) that defines a color space.

It is used in conjunction with a good image editing software such as Photoshop or Adobe Illustrator.

Often people find the image on their computer screen looks different to the image they have printed. An ICC profile can help rectify this issue by correcting the colors your printer applies to an image.

The end result is a printed image that more closely matches the digital image you are seeing on your computer screen.

Would you like to meet sublimation printers in Vietnam?

It is used in conjunction with a good image editing software such as Photoshop or Adobe Illustrator.

Often people find the image on their computer screen looks different to the image they have printed. An ICC profile can help rectify this issue by correcting the colors your printer applies to an image.

The end result is a printed image that more closely matches the digital image you are seeing on your computer screen.

Would you like to meet sublimation printers in Vietnam?

Color Management and Correction

Color Matching

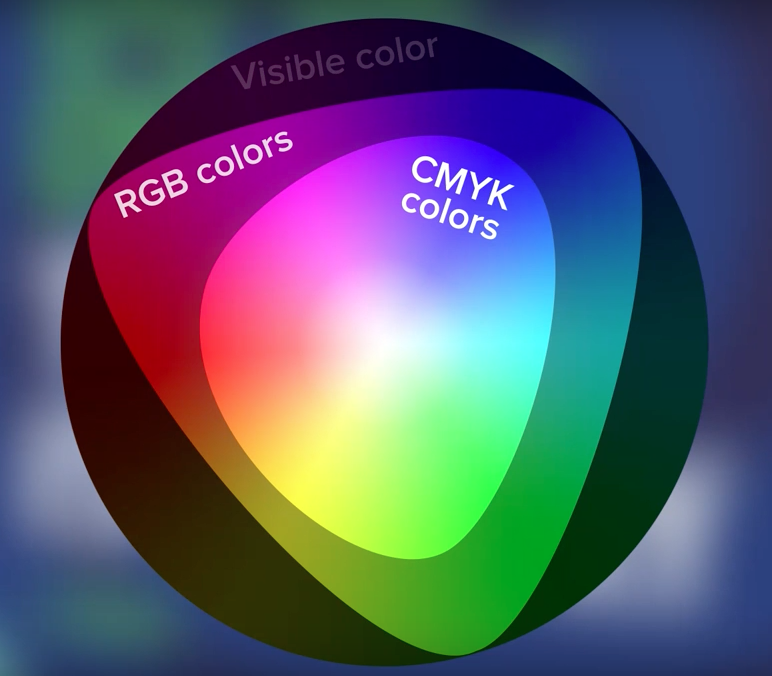

Creating color accurately on paper has been one of the major areas of research in color printing. Like monitors, printers closely position different amounts of key primary colors, which from a distance, merge to form any color. This process is known as dithering. Sublimation printers in Vietnam use this process.

Monitors and printers do this slightly differently however because monitors are light sources, whereas the output from printers reflects light. Monitors mix the light from phosphors made of the primary additive colors: red, green and blue (RGB), while printers use inks made of the primary subtractive colors: cyan, magenta and yellow (CMY). White light is absorbed by the colored inks, reflecting the desired color. In each case, the basic primary colors are dithered to form the entire spectrum. Dithering breaks a color pixel into an array of dots so that each dot is made up of one of the basic colors or left blank.

The reproduction of color from the monitor to the printer output is referred to as color matching. Colors vary from monitor to monitor and the colors on the printed page do not always match up with what is displayed on-screen. The color generated on the printed page is dependent on the color system used and the particular printer model, not by the colors shown on the monitor. Sublimation printers in Vietnam must be very good at color matching.

Color Management

If color is to be an effective tool, it must be possible to create and control consistent, predictable color in a production chain: scanners, software, monitors, printers etc. The challenge is that different devices can't create the same range of colors. It is in the field of color management sublimation printers in Vietnam must excel.

Recognizing the problems of cross-platform color control, the ICC (International Colour Consortium) was formed in March 1994 to establish a common device profile format. The founding companies included Adobe, Agfa, Apple, Kodak, Microsoft, Silicon Graphics, Sun Microsystems, and Taligent. Sublimation printers in Vietnam use the ICC guidelines.

The goal of the ICC is to provide true portable color that will work in all hardware and software environments, and it published its first standard - version 3 of the ICC Profile Format - in June 1994.

There are two parts to the ICC profile; the first part contains information about the profile itself, such as what device created the profile and the second is colormetric device characterization, which explains how the device renders color.

Color Correction

With dye sublimation there is another element of the color control process that has to be addressed. When a dye sublimation transfer sheet is pressed onto a substrate, the ink turns into a gas to bond to the polymers of the substrate. During this “gassing” certain colors will ‘shift’ so the finished product will not look like the original image on the screen or the image that printed out on the transfer paper. Color correction is the art of adjusting this color transformation so that you can produce the best quality results on your substrate. Sublimation printers in Vietnam must master color correction.

(It should be noted that the colors of the ink printed on the transfer paper are very different from the final image that is created when heat and pressure is applied due to the chemical characteristics of the dye sublimation process. Thus, there is no need to consider the ink colors at this stage when performing any type of color correction.)

When using dye sublimation ink, color correction needs to be addressed for each individual printer and ink combination. In extreme circumstances color correction may be needed for every combination of printer/ink/substrate and transfer paper. However, extensive testing has shown that in most cases good quality transfer paper does not affect the final color, therefore it’s recommended that you only deal with high quality papers. Ask your sublimation printers in Vietnam what paper they are using.

It should be noted, that suitable substrates for sublimation will have white surfaces. However, there are varying degrees of white, which technically could have an affect on the colors of the final image. But in reality, these varying shades have little or no effect on the finished appearance, and thus it’s not necessary to perform color correction for every shade of white surface you come in contact with. What shade of white are your sublimation printers in Vietnam using?

Another factor that must be considered when addressing color correction is that each device that deals with an image, whether it's your scanner, digital camera, monitor or printer has a unique way of handling color. The subtle differences among these devices must be overcome and replaced by consistency of color interpretation by known standards.

Different Methods Of Color Correction

There are two basic methods of color correction for dye sublimation: ICC profiles and custom printer drivers. Though both methods are somewhat similar, they have specific differences.

ICC (International Color Consortium)

An ICC (International Color Consortium) profile is basically a software file that ensures that when a specific color is selected on the computer screen, the designated color is consistently and correctly delivered on the substrate. Think of it as a color matching program, as the screen color rarely produces exactly the same output color.

To use this method you must work with ICC compliant software (e.g. Photoshop, Corel). The profile will be placed in the output stage of printing and the manufacturer’s (OEM) printer driver will be set to ‘No Color Adjustment’. This method will color correct the image and then send the data to the printer without affecting the colors further.

Color correction profiles for dye sublimation have their own unique problems. Under normal profile creation when sublimation printers in Vietnam have printed out the color swatch for testing, the profiling software knows how to adjust the colors to print out the correct ones. When a dye sublimation transfer is pressed onto a substrate the ink turns into a gas and while in this state the colors change properties. This change can be quite dramatic (e.g. some blues look like green on paper) and it is therefore impossible to judge whether the print is correct or not. Thus, many sublimation printers in Vietnam create custom profiles that correlate the screen color to the final sublimated color, rather than just to the ink color.

Custom printer drivers

Custom printer drivers are software programs that have color correction built into the printer control system. The advantage of this method is the ability to use non-ICC compliant software (e.g. Paint Shop Pro, Print Shop) as well as ICC compliant software, as the color correction is performed at the printer driver stage. In addition, it’s easier and less technical to use a custom printer driver than it is to use an ICC profile. What ICC profile will the sublimation printers in Vietnam use?

The PowerDriverTM software inserts a color palette (ColorSureTM) into the graphics program so that a user can select colors from the palette while working on images and thereby ensuring that the correct “final” color will be consistently produced during the sublimation production process.

It is suggested that the user print out and sublimate the entire palette to a pure white substrate, and then retain this color “chart” as a visual reference for working with the ColorSureTM palette. The printed chart demonstrates the exact color that is created via sublimation (plus the RGB settings), so the graphic designer has an accurate reference when choosing the proper colors for the image being created.

Best Advice

Start with Tech Packs

Reverse Engineer your MOQs

Choose your QC Levels

Look Up Import Tax

Calculate Shipping Costs

Reverse Engineer your MOQs

Choose your QC Levels

Look Up Import Tax

Calculate Shipping Costs

Services

Consulting

Factory Introductions

Design and Development

A - Z Sublimation Garment Production

Factory Introductions

Design and Development

A - Z Sublimation Garment Production